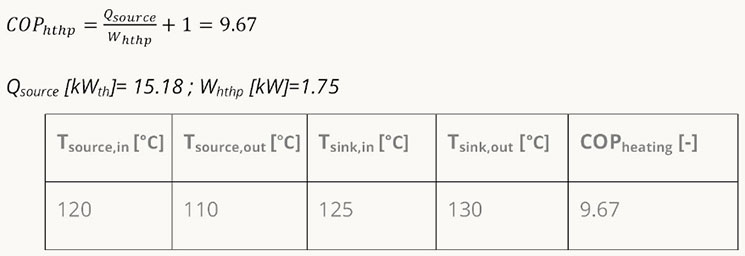

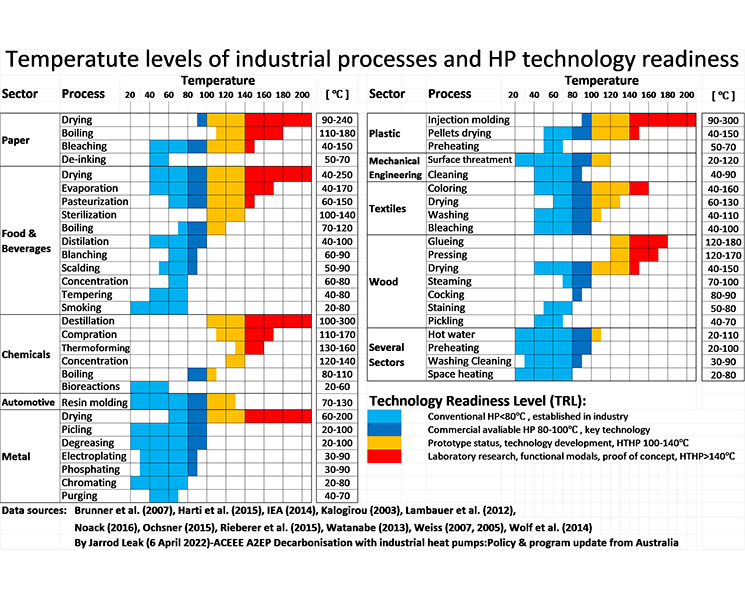

Product is a hybrid electrical/thermal energy storage composed by a novel high temperature heat pump and the thermal energy storage tank. Integration of heat pump and storage is optimized as operating temperatures and pressure ratios are specifically chosen for highest operational efficiency. Calculated COP is around 9.67. Working fluid: R1233zd(E)

Highly Efficient High Temperature Heat Pumps (HTHP)

with Low-Cost Thermal Energy Storage (TES)

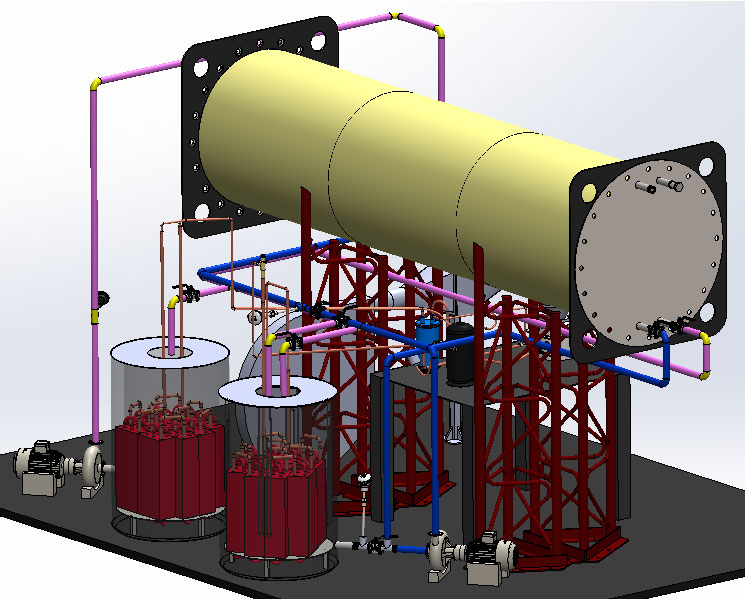

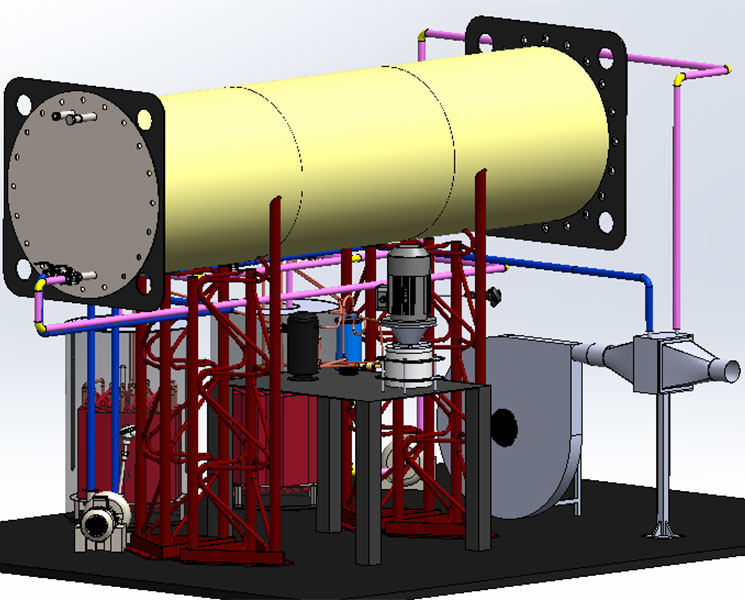

High Temperature Heat Pump (HTHP) + Thermal Energy Storage (TES)

- Standard and modular units HTHF-15 and HTHF-30 (15kW-30kW)

- Offered with three different non-pressurized TES configurations:

- µTES-PCM, µTES-HTF and µTES-C (modular approach)

- Heat exchangers (HXs): evaporator and condenser have each 13.05 m2 heat transfer surfaces. 29m finned copper piping. Hot oil circulation pumps move 100 Lt HTF within HXs

- Flexible operation: heat pumps operate most efficiently at 100% compressor capacity and with a TES. Thus, it is easy to follow “plant heat-load demand” mode of operation.

Charging TES with HTHP and discharging TES through oil-to-air heat exchanger

- Application: homes, schools and Industrial waste heat and processes

- Low-cost decarbonization solution for lower heat grades such as; heat from micro-size concentrated solar blocks (up-to 100°C); Underground/geothermal heat sources (up-to 100°C); excess electrical power heaters from roof-top PVs stored as heat inside TES (PV charges TES in 5 hours)

- 100 kWh modules of µTES charge and discharge in 6 hours

- Up to 120°C: µTES-PCM contains PCM encapsulated tubes

- Up to 150°C: µTES-HTF contains heat transfer fluid (HTF)

- Up to 150°C Concrete filled µTES-C

- HTHP-15 (15 kW) charges a minimum of 4 µTES-PCM modules with a total weight less than 2.5 t. Nominal compressor input is 1.75 kWe.

- HTHP power units (15kW-30kW) are modular (parallel assembly)

- HTHP-15 footprint LxW: 1m x 1m, HTHP weight-alone: 250 kg

- µTES-PCM footprint LxW: 4m x 2m (modules of 25 kWh)

- HTHP-15 charges the TES tank at a rate of 16.67 kWth

- Modular capacity installations from 15 kW to 480 kW up to 8 compressors per unit. Highly flexible industrial operations,

- HCFO-1233zd(E) working fluid is harmless. Class A1, no toxicity and no flammability. ODP = 0, GWP < 5.

- Leak-proof pressure seals on the shaft side

- Compressor driven by a 2kWe open motor with controller

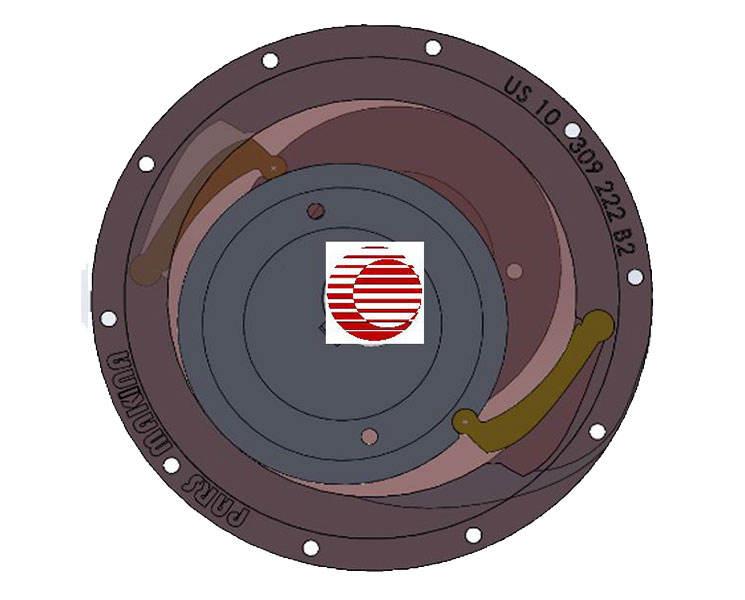

- Compressor technology: patented double hinged arc vane rolling piston

- Lubrication: POE-SL-68

- HTHP pilot plant at TRL6 as the technology is demonstrated in industrially relevant environment.

- Heat Transfer Fluid (HTF) on sink and source side is mineral based Renotherm 320 with high thermal stability up to 320°C.

Project: HTHP-15 is demonstrated at full scale in the context of InnoSolPower (CSP ERA-NET grant agreement No. 838311).

- Tested operating temperature are between 100°C-130°C and pressures are between 12.4 bar-19.6 bar.

Results are presented to InnoSolPower Advisory Group Members.

- Key Performance Indicators (KPIs) ar: high density, high latent heat of fusion, high specific heat, melting point near the required operational temperature (120°C), high thermal conductivity, low vapor pressure, high thermal stability, high chemical stability, low cost, high market availability and low tank size.

Heat supply capacity: Modules of 15kW-30kW-60kW, combined units up to 480 kW

Temperature range: maximum supply temperatures 150°C. HTHP can supply maximum supply heat up to 150°C, such as maximum temperature lift of 20°C. Maximum temperature glides in source is 20°C and at the sink, 25°C

Specific investment cost for installed system without integration: Combined HTHP-15 + µTES-PCM cost: 1500 €/kW

TRL level: TRL6

Expected lifetime: 25 years with regular yearly maintenance

HVAC Compressor

for Refrigeration and Heat Pump Applications (-20°C up to 150°C)

High Temperature Heat Pump (HTHP) + Thermal Energy Storage (TES)

- Rotor, housing and end plates are manufactured from high performance stainless steel

- Material can be magnetized and hardened for near-perfect grind finish.

- Low thermal expansion coefficient.

- 51HRC hardness is conserved up to 450°C

- Primary and secondary balances are achieved with two identical stages, placed 180 degrees out of phase to each-other.

High Performance at Low Speeds

- Low local cavitation risk (low speed, very strong rotor architecture) compared to centrifugal compressors

- Clearances much lower than screw compressors

- Manufacturing cost down (No need for 5-axis CNC (only 3-axis needed), high tolerances are obtained through cost effective grinding and EDM wire technology (electrical discharge machining)

- No reed valves at inlet and outlet of compressor

- Balanced and quiet operation (because no valves)

Technological Advantages

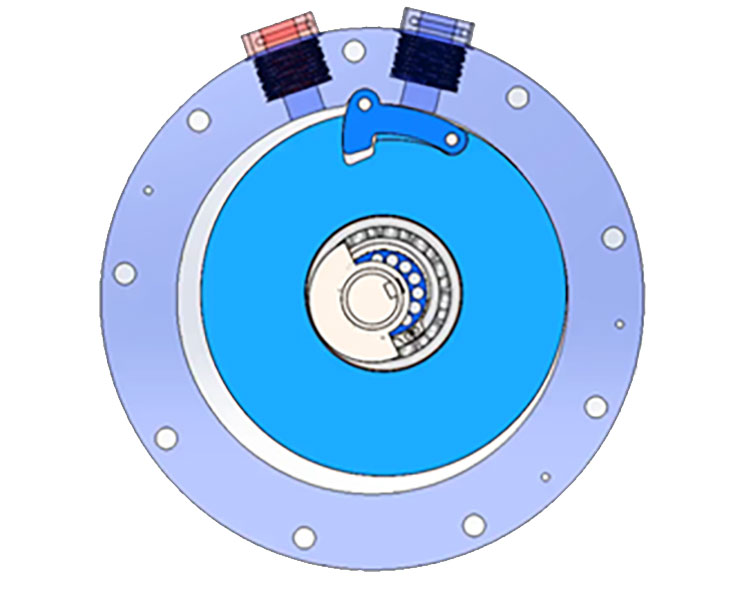

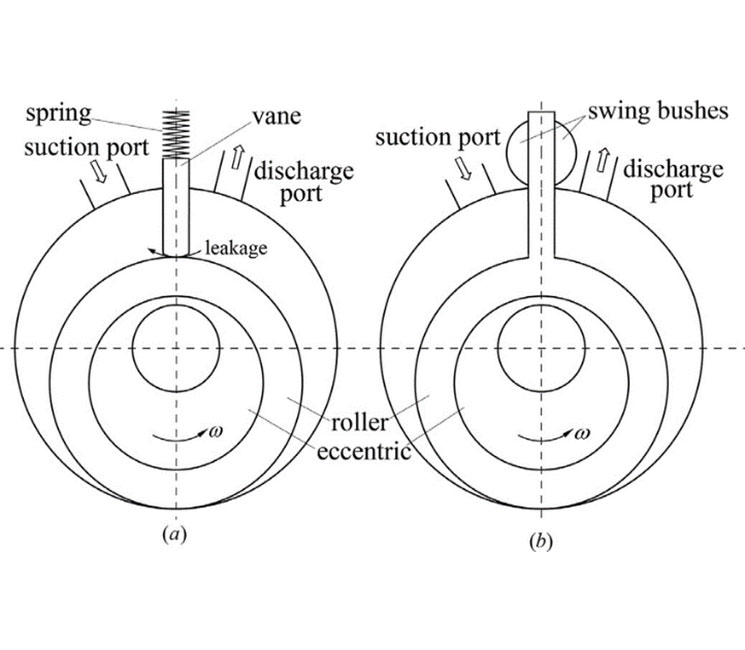

Stae-of-the-Art technology: Dyadaxis Ltd. double hinged arc vane: compact, no leakage, no friction, suction: blue, discharge: red

- Semi-hermetic architecture.

- Electrical motor is operating at expander outlet temperature (35°C) and pressure (40.7bar),

Direct coupling allows ease of compressor-expander alignment

Current technologies:

Left: Spring loaded vane: leakage and friction,

Right: Swing vane: no leakage but vane-swing vane friction

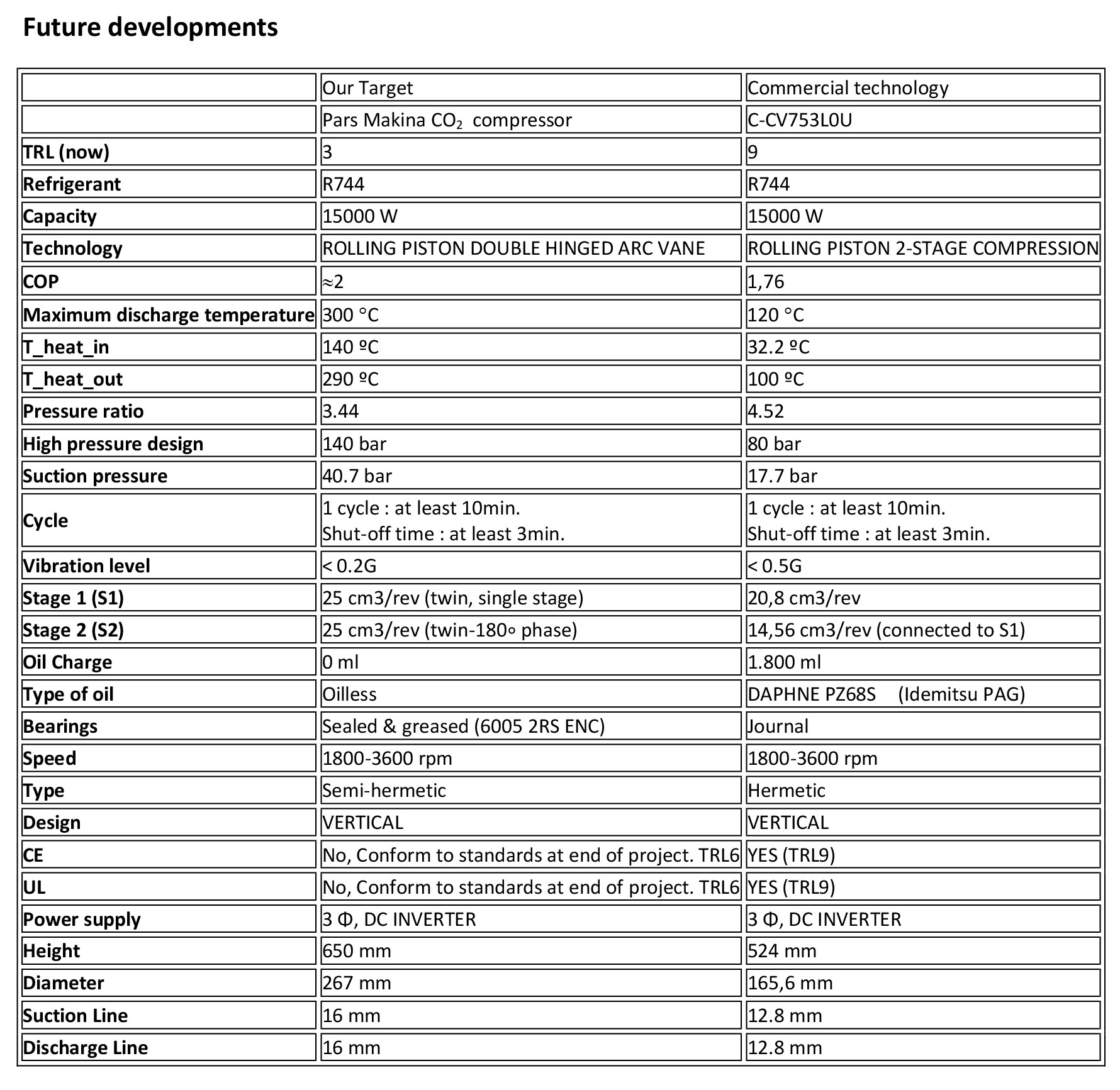

Future Developments