Published at :

https://heatpumpingtechnologies.org/project68/task1/

September 2025

Published at :

https://heatpumpingtechnologies.org/project68/task1/

September 2025

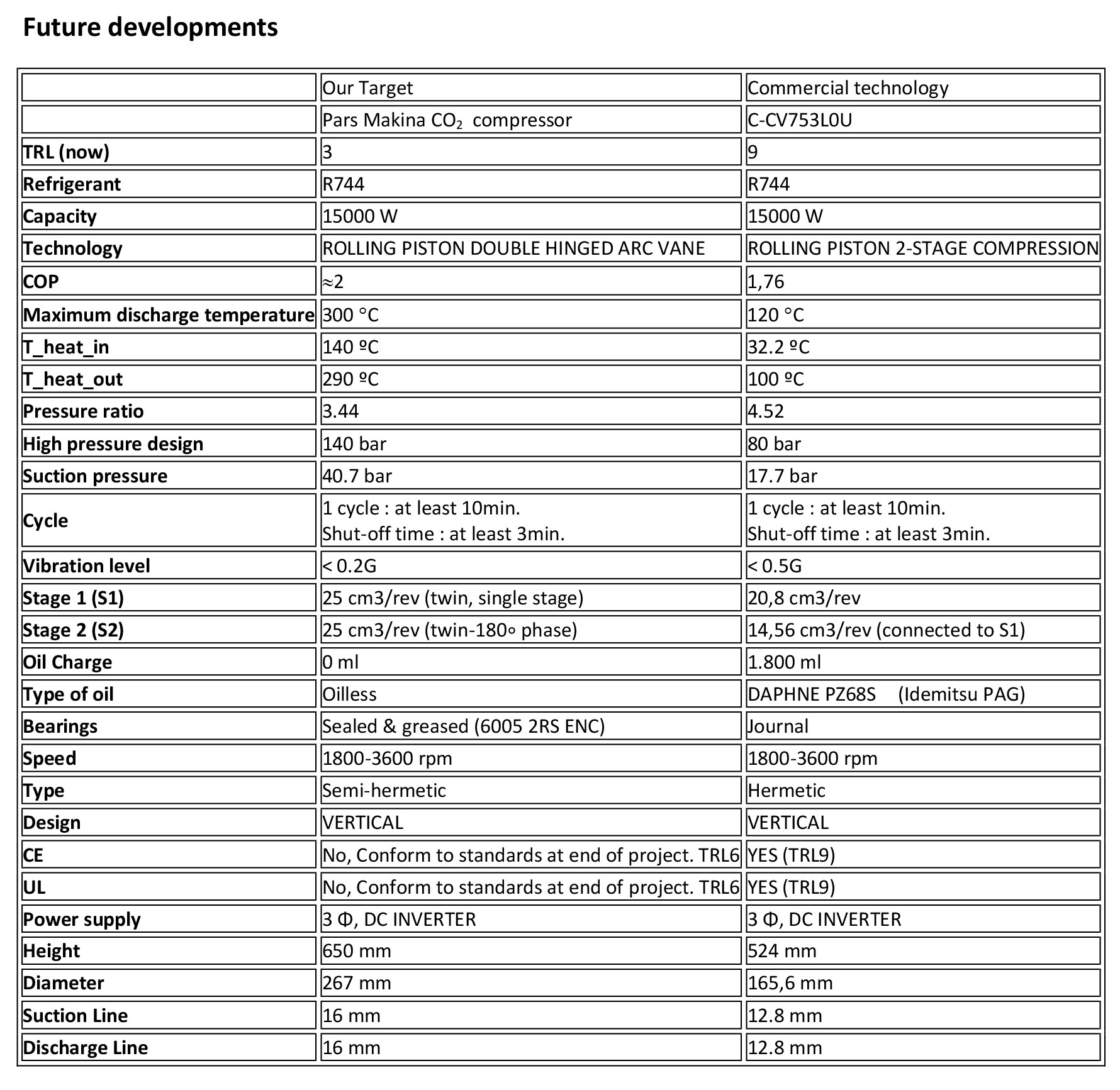

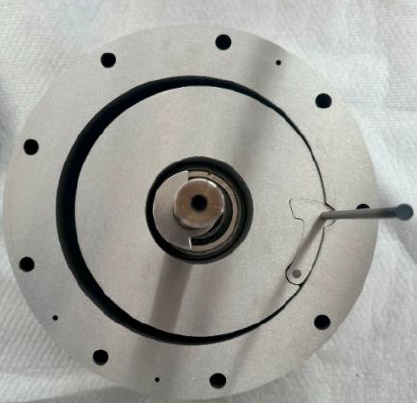

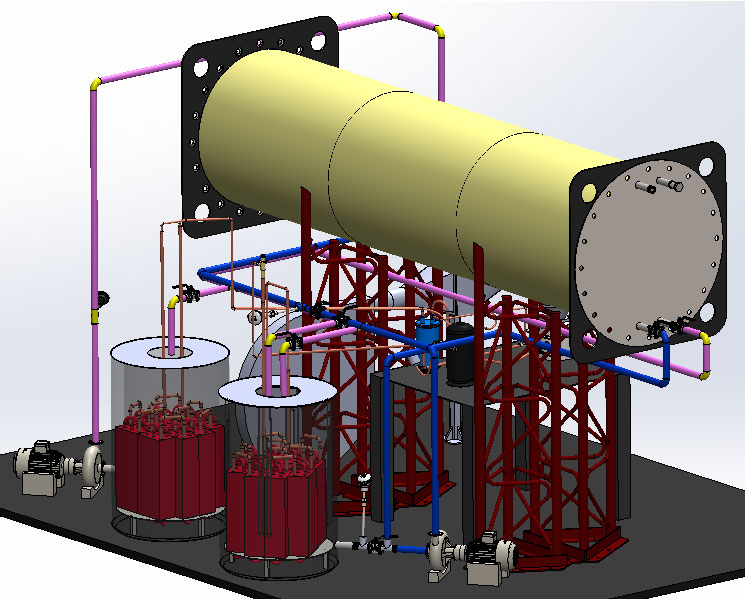

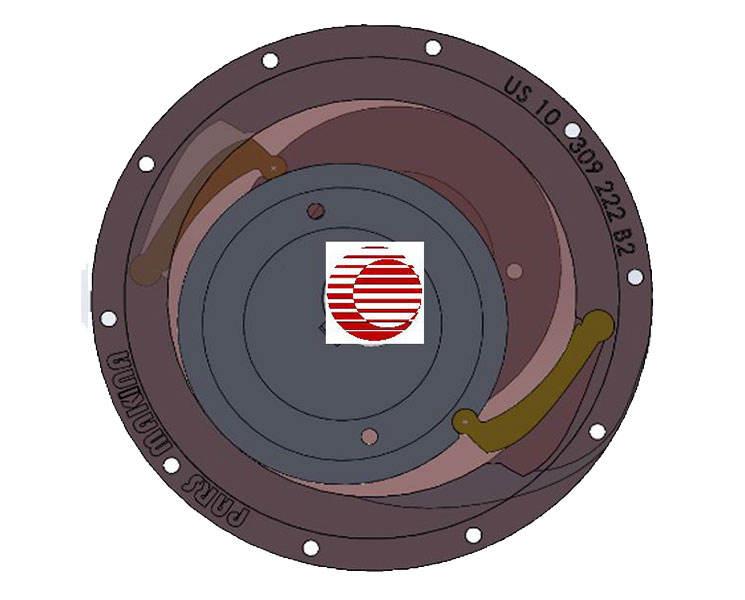

Figure 1: HTHP Equipped with High Precision Double Hinged Arc Vane Compressor

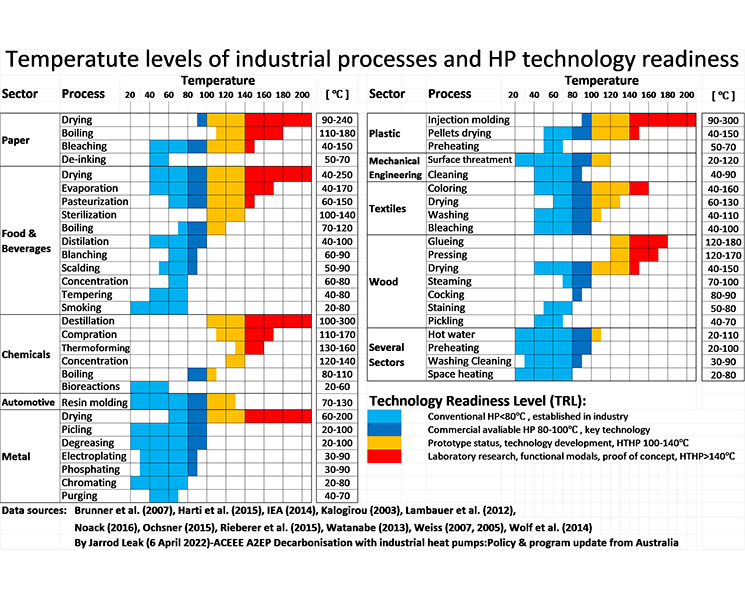

Summary of technology

At the heart of the HTHP, there is a novel double hinged arc vane compressor (Fig.1) driven by a vertically placed electrical motor. Main features are listed below.

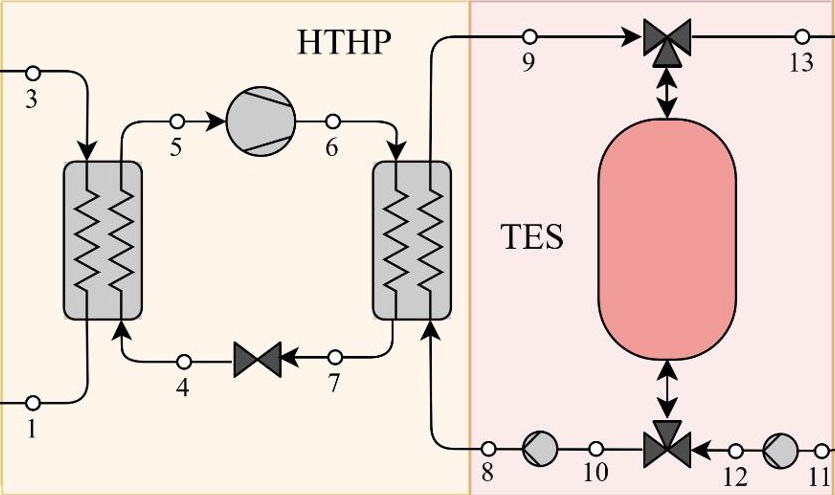

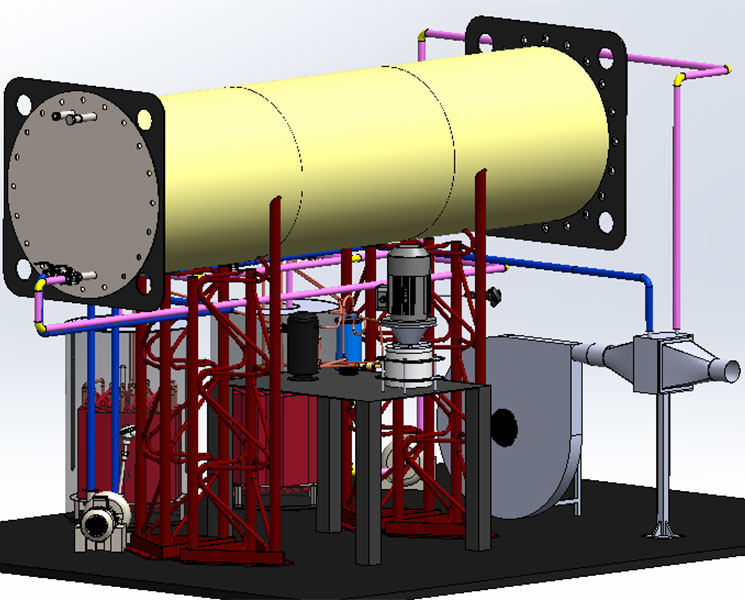

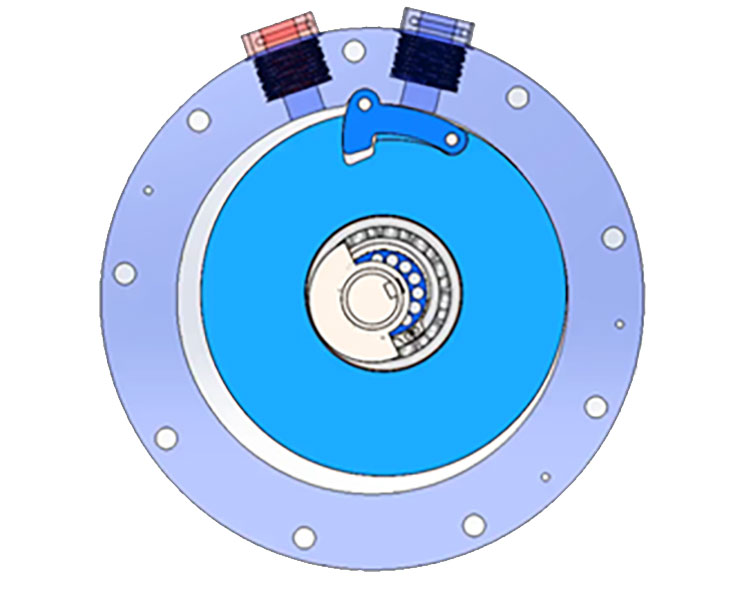

Figure 2: Operational HTHP+TES prototype configuration

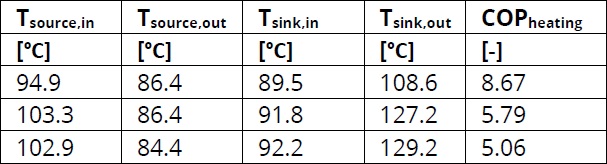

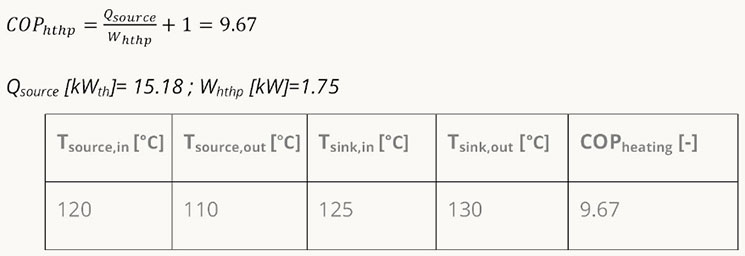

Table 1: Measured performance on factory test bench.

Project example

InnoSolPower project has been supported under the

umbrella of CSP-ERA.NET (Cofound ERA-NET Action, G.A. N°

838311). The project is now completed. This technology is

highly flexible for different industrial operations and heat

needs. Pars Makina Ltd (PML) has designed, developed,

manufactured and tested a double hinged arc vane

compressor for a high temperature heat pump (HTHP) with

a discharge temperature well over 130°C. Closed volume

compression allows the pumping of a nominal mass flow

rate around 0.14 kg/s of R1233zd(E) with very high

volumetric efficiencies.

Main thermodynamic performance indicators are:

Volumetric efficiency: the smaller the internal leakage, the

more the volumetric efficiency increases. Volumetric

efficiency is over 90%,

Compressor pressure ratio: 1.58 for R1233zd(E),

Compressor volume ratio: 1.72 for R1233zd(E),

Compressor discharge pressure: 19.55Bar for R1233zd(E),

Volumetric flow rate: 2.9Lt/s for R1233zd(E),

Reliability & Operating Life Expectancy: roll-cake topology of

hinged-vane rolling piston compressor and oil film prevent

direct contact with the internal surface of the cylindrical

housing. The compressor can operate for over 100,000

hours (2 to 3 times that of rotary screw compressors)

without wear.

Main economic performance indicator: to provide low cost

and very efficient high temperature industrial heat pump

compressors. Our potential customers are heat pump

manufacturers, heat pump installers and repair shops,

HTHP technology extensions: supercritical CO2 (R744)

compressors and expanders.

Installation and test start date: January 2024

FACTS ABOUT THE TECHNOLOGY

Heat supply capacity: Modules of 25 kW-75 kW- 125 kW, combined units up to 1 MW

FACTS ABOUT THE TECHNOLOGY

Heat supply capacity: Modules of 25 kW-75 kW- 125 kW, combined units up to 1 MW

Supply Temperature, max: 150 °C

Temperature lift, max: Maximum temperature lift is 50°C. Maximum temperature glide at the source is 20°C and at the sink is 40°C.

Working fluid: R1233zd(E)

Heat carrier: Mineral-based heat transfer oil

Compressor technology: Patented rotary doubled hinged arc vane rolling piston

Specific investment cost for installed system without integration: 570€/kW (HTHP), 200€/kW (compressor)

TRL level: TRL6

Operational hours achieved: 2400 hours

Expected lifetime: 25 years with regular yearly maintenance

Size: HTHP 125 kWth compressor alone: weight about 250 kg and with a footprint less than 1 m2. HTHP + TES: weight 2500 kg and footprint 8 m2

Contact information

Dr. Sinan Akmandor, Pars Makina Ltd

Published at :

https://heatpumpingtechnologies.org/annex58/task1/

Product is a hybrid electrical/thermal energy storage composed by a novel high temperature heat pump and the thermal energy storage tank. Integration of heat pump and storage is optimized as operating temperatures and pressure ratios are specifically chosen for highest operational efficiency. Calculated COP is around 9.67. Working fluid: R1233zd(E)

High Temperature Heat Pump (HTHP) + Thermal Energy Storage (TES)

Charging TES with HTHP and discharging TES through oil-to-air heat exchanger

Project: HTHP-15 is demonstrated at full scale in the context of InnoSolPower (CSP ERA-NET grant agreement No. 838311).

Results are presented to InnoSolPower Advisory Group Members.

Heat supply capacity: Modules of 15kW-30kW-60kW, combined units up to 480 kW

Temperature range: maximum supply temperatures 150°C. HTHP can supply maximum supply heat up to 150°C, such as maximum temperature lift of 20°C. Maximum temperature glides in source is 20°C and at the sink, 25°C

Specific investment cost for installed system without integration: Combined HTHP-15 + µTES-PCM cost: 1500 €/kW

TRL level: TRL6

Expected lifetime: 25 years with regular yearly maintenance

High Temperature Heat Pump (HTHP) + Thermal Energy Storage (TES)

High Performance at Low Speeds

Technological Advantages

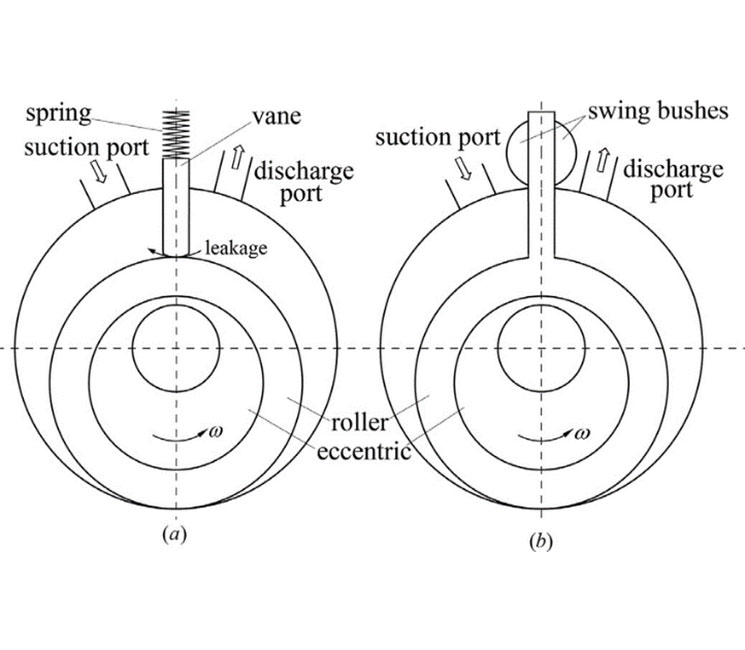

Stae-of-the-Art technology: Dyadaxis Ltd. double hinged arc vane: compact, no leakage, no friction, suction: blue, discharge: red

Direct coupling allows ease of compressor-expander alignment

Current technologies:

Left: Spring loaded vane: leakage and friction,

Right: Swing vane: no leakage but vane-swing vane friction

Future Developments